Swing Arm Deflasher

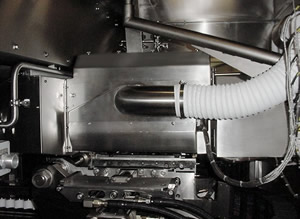

Our Swing Arm Deflasher is designed to be incorporated downstream of our B/F/S machine, typically outside of the cleanroom. This unit is designed to deflash cards of 0.5 to 20mL containers after moving along a conveyor. A swing arm motion extracts the finished containers utilizing a pick and place device, placing them down onto a product exit conveyor. At that point they exit in an orientated manner, being available for your further inspection checks, process, or packaging.

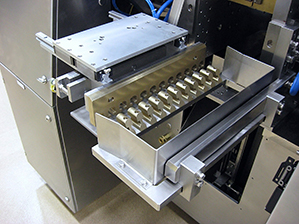

Scrap is controlled and moves to an exit scrap conveyor and then integrates to your removal system. The control system is within its structure and totally independent of the B/F/S machine. The punch and die tooling is hydraulically actuated and secondary motions are pneumatically driven. Power, hydraulic, and pneumatic energy is sourced from the B/F/S machine.